Finding the right gearbox for your industrial setup in Australia can feel like a big task. You need something reliable, something that fits the job, and you need to know where to get it without a hassle. This guide is here to help you figure out what you need and point you toward a good wholesale gearbox supplier Australia has to offer.

Key Takeaways

- Figure out exactly what kind of gearbox your industrial needs require, including its specs and how much power it needs.

- Look for a wholesale gearbox supplier in Australia that has a good track record and knows their stuff.

- Compare suppliers based on their product selection, how easy they are to work with, and their prices.

- Understand Australian standards and the benefits of working with local suppliers for easier logistics.

- Build a strong relationship with your supplier for ongoing support and reliable service.

Understanding Your Industrial Gearbox Needs

Before you even start looking for a supplier, you really need to know what you’re after. Buying the wrong gearbox can lead to all sorts of headaches down the line, from equipment failure to costly downtime. So, let’s break down how to figure out exactly what your industrial setup requires.

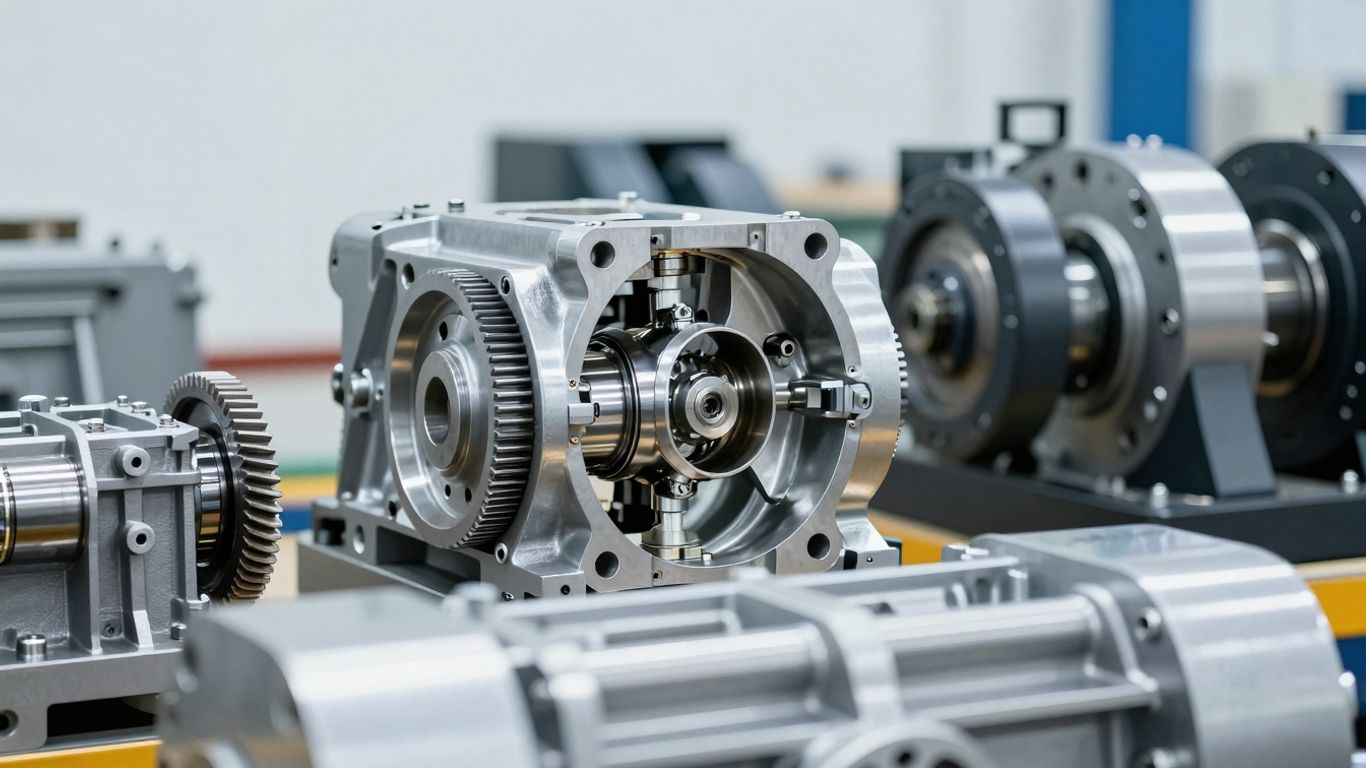

Identifying the Right Gearbox Type

Gearboxes aren’t one-size-fits-all. There are several main types, and picking the correct one is the first step. Think about the kind of motion and speed reduction you need. Some common types include:

- Helical Gearboxes: Great for high speeds and efficiency, often used in conveyors and general machinery.

- Worm Gearboxes: Known for their high reduction ratios and ability to lock output shafts, useful for lifting equipment and indexing.

- Planetary Gearboxes: Compact and powerful, offering high torque density and precise motion control, ideal for robotics and servo applications.

- Right-Angle Gearboxes: Used when you need to change the direction of rotation by 90 degrees, common in packaging and material handling.

Key Specifications for Industrial Applications

Once you have a general idea of the type, you need to get specific. These details are what suppliers will ask for, and they’re critical for performance.

- Gear Ratio: This tells you how much the output speed is reduced compared to the input speed. A higher ratio means slower output speed and more torque.

- Input Speed: The speed at which the motor will drive the gearbox, usually measured in RPM (revolutions per minute).

- Output Speed: The desired speed of the driven equipment.

- Mounting Orientation: How the gearbox will be positioned (e.g., horizontal, vertical, shaft up/down). This affects lubrication and cooling.

- Enclosure Rating (IP Rating): This indicates protection against dust and water, important for harsh environments.

Considering Load Capacity and Torque Requirements

This is where things get serious. You need to know how much force your gearbox will have to handle. The gearbox must be rated to handle the maximum torque your application will demand, with a safety margin.

- Torque: This is the rotational force. You’ll need to calculate the required output torque, considering peak loads and starting torque. It’s usually measured in Newton-meters (Nm) or pound-feet (lb-ft).

- Service Factor: This is a multiplier that accounts for the type of load (e.g., light, medium, heavy, shock loads) and how many hours per day the gearbox will operate. A higher service factor means the gearbox needs to be more robust.

Getting these specifications right upfront saves a lot of trouble. It’s better to over-engineer slightly than to have a gearbox fail under pressure. Think about the worst-case scenario for your operation and spec for that.

When you’re looking at options, especially for specific brands like Ford gearboxes, it’s a good idea to check for certifications like IATF 16949 or ISO 9001. Suppliers should also be able to provide documentation like material certificates to back up their quality claims. Verify their certifications to ensure you’re getting a reliable product.

Finding a Reputable Wholesale Gearbox Supplier Australia

So, you’ve figured out exactly what kind of gearbox your industrial setup needs. That’s a big step! Now comes the part where you need to find someone reliable to actually supply it. In Australia, there are quite a few options, but not all suppliers are created equal. You want someone who knows their stuff and won’t leave you hanging when things go wrong.

Evaluating Supplier Experience and Reputation

When you’re looking for a supplier, don’t just go for the first name you see. Do a little digging. How long have they been in business? What are other companies saying about them? A supplier with a solid track record and positive reviews is usually a safe bet. It’s like choosing a mechanic; you want someone who’s been around and has happy customers. Look for suppliers who have been serving the Australian market for a while, as they’ll likely understand local needs and regulations better. Some companies, like Industrial & Automotive Parts (IAP), have built a reputation for reliability and trust over many years.

Importance of Product Range and Availability

Think about what you might need down the line. Does the supplier have a wide variety of gearboxes and related parts? It’s super convenient if you can get most of what you need from one place. This saves you time and hassle. Also, check if they keep popular items in stock. Nothing is more frustrating than needing a part urgently and being told it’s weeks away. A good supplier will have a decent inventory or at least a clear process for getting what you need quickly. Companies like Gearboxes Transmissions Autos Australia pride themselves on offering premium gearboxes and fast nationwide delivery.

Assessing Customer Service and Support

This is a big one. What happens when you have a question or, worse, a problem? A good supplier will have knowledgeable staff who can answer your technical questions and help you troubleshoot. They should be responsive and easy to get in touch with. You don’t want to be stuck on hold forever or get emails that go unanswered. Good customer service can make all the difference, especially when you’re dealing with complex industrial equipment. It’s not just about the sale; it’s about the ongoing support.

Finding the right supplier isn’t just about the price tag. It’s about building a relationship with a company that understands your business and can consistently provide the quality products and support you need to keep your operations running smoothly.

Key Factors When Choosing a Wholesale Gearbox Supplier

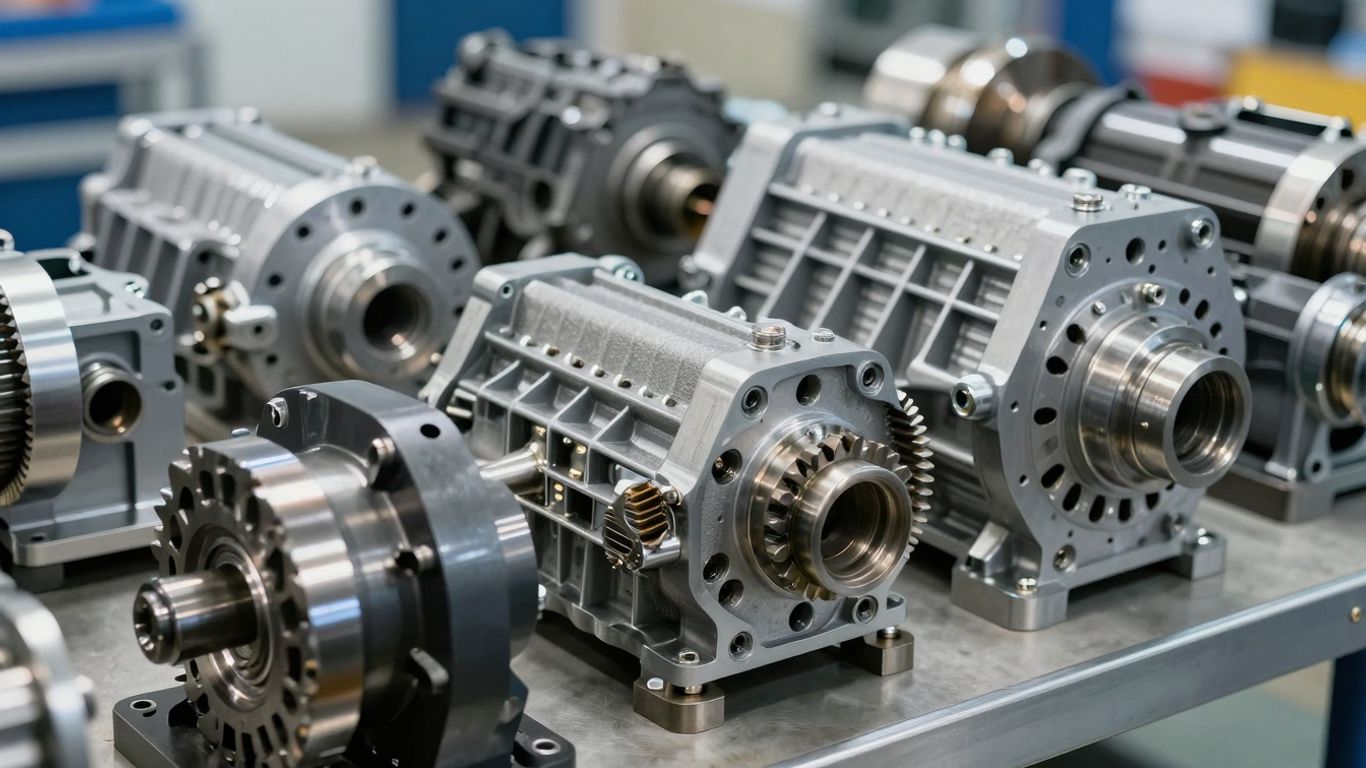

Quality Assurance and Brand Partnerships

When you’re looking for gearboxes, especially for industrial use, you can’t just grab the first thing you see. Quality is really important here. You want to know that what you’re buying is going to last and won’t break down when you need it most. That’s why checking out a supplier’s quality control processes is a good idea. Do they test their products? Do they have any certifications? Also, think about the brands they carry. Suppliers who partner with well-known, reputable manufacturers often mean they’re serious about quality. It’s like buying a car – you generally trust a brand with a good track record.

Competitive Pricing and Value Proposition

Of course, price matters. You’re running a business, and every dollar counts. But don’t just go for the cheapest option. Think about the overall value. A slightly more expensive gearbox that’s built better and lasts longer might actually save you money in the long run. It’s about getting the most bang for your buck. Ask suppliers about their pricing structure, any bulk discounts, and what’s included. Sometimes, a supplier might offer better support or faster delivery, which adds to the value even if the sticker price is a bit higher.

Reliability and Consistent Supply Chain

Imagine you’ve got a big project lined up, and you need a specific gearbox, but your supplier tells you it’s out of stock or will take weeks to arrive. That’s a nightmare scenario. You need a supplier who can consistently provide the parts you need, when you need them. This means they need a solid supply chain. Ask them about their stock levels, lead times, and how they handle unexpected demand. A reliable supplier means fewer headaches and less downtime for your operations.

Here’s a quick look at what to consider:

- Product Range: Does the supplier have a wide variety of gearbox types and brands?

- Availability: Do they keep common models in stock?

- Lead Times: How long does it typically take to get an order, especially for less common items?

- Warranty: What kind of warranty do they offer on their gearboxes?

Finding a supplier that understands the urgency of industrial needs is key. You don’t want to be left waiting when a critical piece of equipment is down. A good supplier will have systems in place to get you what you need quickly and efficiently.

Navigating the Australian Market for Gearboxes

Understanding Local Industry Standards

When you’re looking for gearboxes in Australia, it’s good to know what standards are generally followed. Most suppliers will work with international standards like ISO, but it’s always worth checking if they have specific certifications or if their products meet Australian safety and performance regulations. This is especially true for industries like mining or agriculture, where equipment has to be tough and reliable. You don’t want to end up with a gearbox that doesn’t quite fit the bill for local conditions or legal requirements. Paying attention to these details upfront can save a lot of headaches down the road.

Benefits of Sourcing from Australian Suppliers

Buying from suppliers based in Australia has its perks. For starters, you often get quicker delivery times. Instead of waiting weeks for something to ship from overseas, you can usually get what you need much faster. This is a big deal when your machinery is down and you need parts ASAP. Plus, dealing with a local company means easier communication. You can talk to someone who understands the local market and can offer support in your own time zone. It also helps support local businesses, which is always a nice bonus.

Here are a few reasons to consider Australian suppliers:

- Faster Delivery: Reduced shipping times mean less downtime for your equipment.

- Easier Communication: Local support and understanding of your needs.

- Local Compliance: Gearboxes are more likely to meet Australian standards and regulations.

- Support Local Economy: Your purchase contributes to Australian businesses.

Logistics and Delivery Across Australia

Australia is a massive place, so how your supplier handles logistics is pretty important. Think about where your business is located and how easily a supplier can get parts to you. Some suppliers have warehouses in major cities, which can speed things up. Others might rely on third-party couriers, so it’s good to ask about their delivery network and typical transit times. If you’re in a remote area, this becomes even more critical. You’ll want a supplier who has experience shipping to all corners of the country and can provide reliable tracking information. It’s not just about getting the gearbox; it’s about getting it when and where you need it without a fuss.

Building a Long-Term Supplier Relationship

Finding a good wholesale gearbox supplier in Australia is one thing, but making that relationship last is another. It’s not just about getting the parts you need; it’s about building a partnership that helps your business run smoother and more efficiently. Think of it like any good relationship – it takes effort from both sides.

Communication and Responsiveness

When you’re in the middle of a production line issue, the last thing you want is to be left hanging. A supplier who gets back to you quickly, whether it’s a quick email reply or a phone call, makes a huge difference. It shows they value your business and understand that downtime costs money. This responsiveness is key when you need to order parts or get advice.

- Prompt replies to inquiries: Aim for suppliers who respond within 24 hours.

- Clear communication channels: Know who to contact for different issues.

- Proactive updates: A good supplier will let you know about potential delays before they become a problem.

Technical Expertise and Problem-Solving

Sometimes, you might not be entirely sure what gearbox you need, or you might run into a tricky installation problem. A supplier with solid technical knowledge can be a lifesaver. They can help you figure out the best gearbox for your specific setup or troubleshoot issues you’re facing. It’s like having an extra expert on your team, without the added payroll. They can help you avoid costly mistakes and get the most out of your equipment. For example, understanding the nuances of different gearbox types can prevent premature wear and tear.

Commitment to Customer Satisfaction

Ultimately, a supplier who is committed to your satisfaction is the one you want to stick with. This means they stand behind their products, are fair with returns or warranty claims, and genuinely care about helping your business succeed. It’s about more than just a transaction; it’s about them being invested in your long-term success. This kind of partnership can lead to better pricing over time and a more reliable supply chain, which is a big win for any industrial operation. It’s about building trust, and that’s something you can’t put a price on. They should be focused on local entrepreneurship and supporting Australian businesses.

Wrapping Up Your Gearbox Search

So, finding the right gearbox supplier in Australia might seem like a big task, but it’s totally doable. We’ve talked about what to look for, like checking their stock, how helpful their team is, and if they’ve got a good track record. Companies like Industrial & Automotive Parts and IBS are out there, ready to help you find exactly what you need, whether it’s a common part or something a bit harder to track down. Don’t forget to ask questions and make sure they understand your specific industrial needs. Getting this right means your machinery keeps running smoothly, saving you headaches and money down the road. Good luck with your search!

Frequently Asked Questions

What is a gearbox and why do I need one for my industrial equipment?

A gearbox is like a special set of gears that helps control the speed and power of a machine’s motor. Think of it like the gears on a bicycle; they let you pedal easier uphill or go faster on flat ground. For industrial machines, a gearbox makes sure the motor works at the right speed and has enough strength (torque) to do its job, whether it’s lifting heavy things or moving materials.

How do I know which type of gearbox is best for my needs?

Choosing the right gearbox depends on what your machine does. You need to think about how much weight it needs to move or how much force it needs to apply. Also, consider how fast it needs to spin. It’s a good idea to talk to an expert or look at the machine’s manual to figure out the exact type and size of gearbox that will work best.

What are the most important things to look for in a gearbox supplier in Australia?

When looking for a supplier, make sure they have a good reputation and lots of experience. It’s important they have a wide selection of gearboxes so you can find exactly what you need. Also, check if they offer good customer service and can help you if something goes wrong. A reliable supplier will have the parts you need when you need them.

Why is it better to buy from an Australian supplier?

Buying from an Australian supplier means you’ll likely get faster delivery because they’re closer. They also understand local rules and standards, which can make things easier. Plus, you’re supporting businesses in your own country. Companies like Industrial & Automotive Parts (IAP) and others mentioned have a strong presence and understanding of the Australian market.

What does ‘load capacity’ and ‘torque’ mean for a gearbox?

Load capacity is basically how much weight or force the gearbox can handle without breaking. Torque is like the twisting power the gearbox can deliver. If your machine needs to turn something heavy or apply a lot of force, you’ll need a gearbox with high torque and good load capacity.

How can I make sure the gearbox I buy is good quality?

Look for suppliers who work with well-known, trusted brands. They often have quality checks in place. Asking about warranties and the supplier’s experience with different brands can also give you peace of mind. A good supplier will stand behind the products they sell.