Finding Australia’s best gearbox supplier can feel like a real puzzle sometimes. Whether you’re looking for a whole new unit, someone to fix up your current one, or just a specific part that’s proving impossible to track down, the options can seem overwhelming. This guide is here to help cut through the confusion and point you towards some of the top names in the business. We’ve gathered information on companies known for their quality work, extensive product ranges, and solid reputations across the country. So, if you’re dealing with a tricky transmission issue or planning an upgrade, check out these places.

Key Takeaways

- Wholesale Automatic Transmissions offers a massive selection of automatic transmission parts, including Australian-made heavy-duty coolers and torque converter lock-up kits, catering to many vehicle makes.

- Heavy Automatics is a major Allison Transmission distributor in Australia, providing support and parts for heavy machinery like trucks and buses, with extensive inventory and multiple facilities.

- Mal Wood Automotive is an official Elite TREMEC Distributor with over 40 years of experience, supplying TREMEC transmissions and a wide range of driveline parts for various car models.

- The Australian market for automatic gearboxes is growing as more people prefer automatic cars, leading to a higher demand for related parts and services.

- When picking a supplier, it’s smart to check the quality and how long the parts will last, make sure they are right for your specific vehicle, and consider the supplier’s reputation and the support they give.

Understanding The Shifting Australian Gearbox Market

Shifting Consumer Preferences Towards Automatics

It’s pretty clear that Aussies are really starting to prefer automatic transmissions. Gone are the days when manual gearboxes were the standard for most vehicles. We’re seeing a definite move away from manual setups, with automatics becoming the go-to choice for many drivers. This isn’t just a fad; people want the ease of driving, especially when dealing with city traffic. This shift means there’s a growing need for parts and services focused on these automatic systems. The whole automotive transmission market is expanding, and Australia is right in the thick of it. The commercial vehicle automated manual transmission market is expected to grow significantly, expanding from USD 3,584.4 million in 2025 to USD 7,667.2 million by 2035, showing a compound annual growth rate of 7.9% [649e].

The Growing Demand For Specialized Industrial Gearboxes

With the push for more efficient production lines, things are changing in Australia’s industrial sector. Factories and assembly plants are looking to automate more of their processes. This means a bigger need for reliable gearboxes that can handle constant work and precise movements. Because so many new vehicles are coming with automatic gearboxes, the demand for specialized industrial gearboxes is also picking up. These aren’t the ones you find in your average car; these are the heavy-duty units used in factories and production lines. They’re needed for things like assembly lines and testing equipment that handle these increasingly complex automatic drivetrains. It’s all about making sure the production and upkeep of vehicles with automatic transmissions run smoothly. This is a big part of why the industrial gearboxes market in Australia is seeing more activity. The industrial gearbox market is expected to reach $39.96 billion by 2029, with a projected CAGR of 5.3%. This indicates a period of steady growth for the sector.

Impact Of International Models On Domestic Infrastructure

Australia is becoming more connected to the global automotive scene. A lot of vehicles sold here are made overseas, and this trend is likely to continue. This means our local gearbox suppliers and repair shops will need to be ready to service a wider range of international models. They’ll need access to parts and technical info for gearboxes made in different countries. Building a solid service network that can handle these international transmissions will be important for businesses wanting to stay competitive. It’s about being prepared to fix anything, no matter where it was originally manufactured. This includes keeping up with advanced drivetrain technologies and ensuring parts are available for compact, 4WD-compatible solutions. When car companies bring new models here with advanced gearboxes, Australian suppliers need to be ready. They have to get the right parts and learn how to fix these new systems, making them more knowledgeable about gearboxes from all over the world. Adapting to these international vehicle models is key for local gearbox suppliers.

The automotive industry is constantly evolving, and the heavy-duty truck gearbox sector is no exception. Staying ahead means anticipating shifts in technology, vehicle design, and global manufacturing trends. Suppliers and operators alike need to be adaptable and informed to meet the demands of modern logistics and transportation.

Key Considerations When Choosing Australia’s Best Gearbox Supplier

So, you’re on the hunt for a new gearbox or some parts for your rig here in Australia. It can feel a bit overwhelming with all the options out there, right? Don’t just pick the first place you see. Taking a bit of time to think about a few things can save you a heap of trouble and cash down the track. It’s about getting the right fit for your vehicle and making sure you’re dealing with someone reliable.

Assessing Part Quality and Durability

This is pretty straightforward, but super important. You want parts that are built to last, especially if you’re dealing with heavy-duty applications. Think about what the part is made of and how it was put together. A gearbox takes a beating, so weak materials or sloppy manufacturing will just lead to more problems later on. Look for suppliers who can show you proof of quality, like certifications or warranties. It’s better to pay a bit more upfront for something that won’t break when you need it most.

Verifying Supplier Reputation and Experience

Who are you actually buying from? Do they know their stuff? A supplier with a good track record and years of experience is usually a safer bet. They’ll likely have a better understanding of what works and what doesn’t, and they’ll be more helpful if something goes wrong. Check out online reviews, ask around in forums, or see if they have testimonials from other customers. A supplier that’s been around for a while and has happy customers is a good sign.

Ensuring Vehicle Specificity and Compatibility

This is where a lot of people trip up. You can’t just grab any gearbox and expect it to work. You absolutely need to know your vehicle’s exact make, model, and year. This information is key to getting a gearbox or parts that will fit correctly and function as intended. Using the wrong part can damage your vehicle and be a costly mistake. A good supplier will ask for this information upfront and help you find exactly what you need, not just try to sell you whatever they have in stock.

Getting the right gearbox is like getting the right shoes. If they don’t fit properly, you’re going to have a bad time, no matter how good they look. Make sure you’re getting a part that’s designed for your specific vehicle’s needs and intended use.

Leading Suppliers For Heavy-Duty Truck Gearboxes In Australia

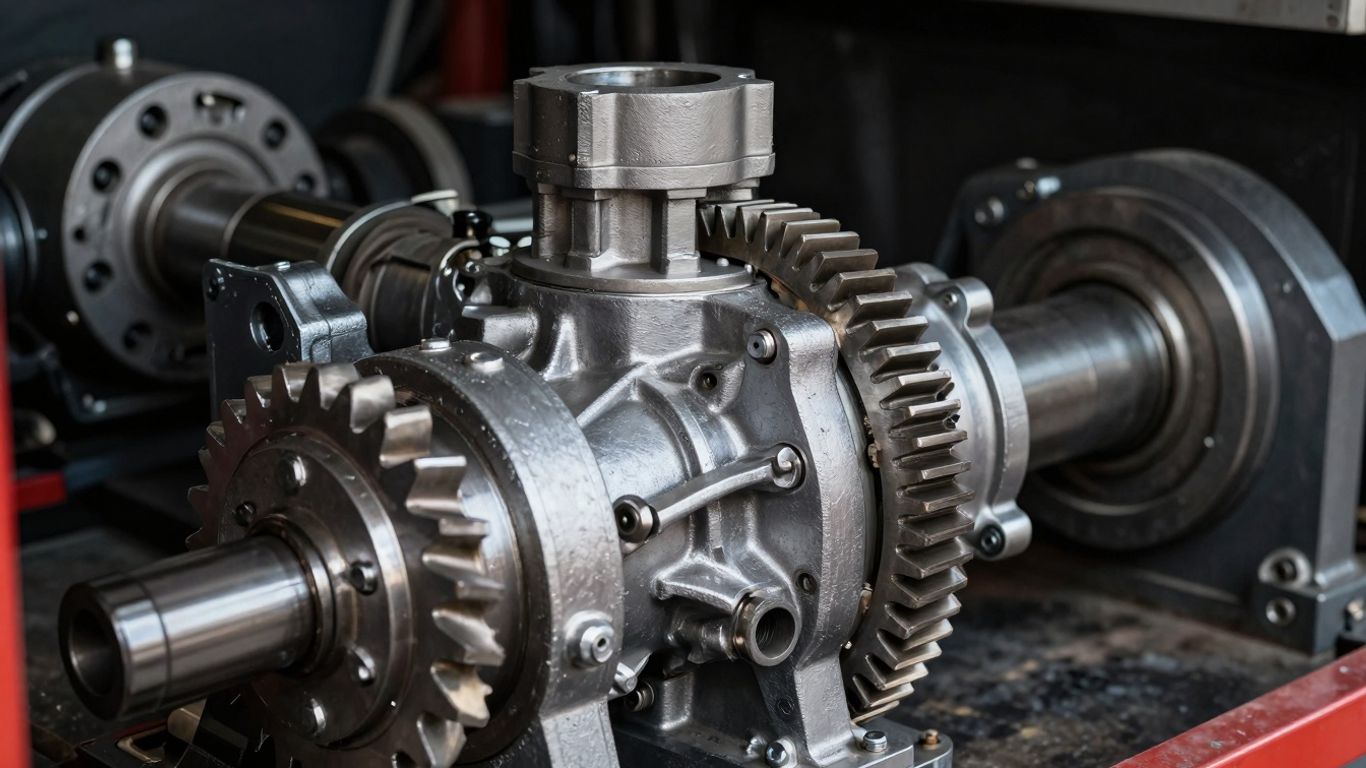

Wholesale Automatic Transmissions: Extensive Parts Selection

When you’re looking for parts for heavy-duty trucks, especially automatics, Wholesale Automatic Transmissions is a name that comes up a lot. They’ve got a massive stock of parts, and they even make some of their own stuff right here in Australia, like heavy-duty coolers and torque converter lock-up kits. This means they can often fit a wide range of trucks, which is pretty handy when you’re trying to keep a fleet moving.

Heavy Automatics: Allison Transmission Specialists

If your heavy truck or bus runs an Allison transmission, Heavy Automatics is a go-to. They’re a big dealer for Allison in Australia, so they know these units inside and out. They’ve got a lot of parts on hand and multiple locations, making them a solid choice for getting your rig back on the road without too much downtime. They handle everything from simple repairs to full rebuilds.

Mal Wood Automotive: TREMEC Driveline Experts

For those who might be looking at performance or specific heavy-duty manual transmissions, Mal Wood Automotive is worth a look. They’ve been around for ages, over 40 years, and are official TREMEC distributors. They sell TREMEC gearboxes and a whole bunch of other driveline parts. While they might be known for performance cars too, their experience means they understand tough gearboxes.

Finding the right gearbox supplier for heavy-duty trucks in Australia can feel like a big task. It’s not just about buying a part; it’s about getting something reliable that will keep your vehicle working. Checking out suppliers who specialize in the type of transmission you have, and who have a good track record, is a smart move. Quality parts and good support can save you a lot of headaches later on.

Here’s a quick look at what makes these suppliers stand out:

- Wholesale Automatic Transmissions: Known for a huge range of automatic parts, including Australian-made components.

- Heavy Automatics: Specializes in Allison transmissions, a common choice for heavy trucks and buses.

- Mal Wood Automotive: Offers TREMEC transmissions and driveline parts, with decades of experience.

When you’re choosing, think about what kind of gearbox you have, how much stock the supplier keeps, and if they have good reviews from other truck owners. It makes a difference.

Navigating The Global Influence On Local Gearbox Supply

Australia’s automotive scene is getting more connected to what’s happening worldwide. A lot of the cars and trucks we drive are built in other countries, and this trend isn’t slowing down. This means our local gearbox shops and suppliers really need to be ready to work on a wider variety of international models. They’ve got to have access to the right parts and the technical know-how for gearboxes made all over the globe.

Adapting To International Vehicle Models

It’s not just about fixing what we’ve always had anymore. The vehicles rolling off ships are bringing new gearbox designs and technologies with them. Suppliers need to keep up. This means stocking parts for transmissions from places like Europe, North America, and Asia. It’s a big shift from just focusing on local or older models. Being able to service these diverse international transmissions is becoming key for businesses wanting to stay competitive. It’s about being prepared to handle pretty much anything that comes through the door, no matter where the vehicle was originally manufactured.

Sourcing Parts For Diverse Global Transmissions

Finding the right parts can be a challenge. You can’t just walk into any old shop and expect them to have a gearbox part for a new European truck or a specialized Japanese 4×4. Suppliers are increasingly looking to international manufacturers for these components. Some regions have become major hubs for gearbox parts. For example:

- China: Provinces like Guangdong and Zhejiang are big players, offering a wide range of parts, often with competitive pricing and faster turnaround times due to good infrastructure and port access.

- Europe: For high-end or specialized European vehicle parts, direct sourcing from European manufacturers or their authorized distributors is often necessary, though it can be more costly.

- North America: For certain American truck or performance vehicle transmissions, North American suppliers are the go-to, especially for specific OEM parts.

It’s about building relationships with these global sources to make sure you can get what your customers need.

Staying Competitive With Evolving Drivetrain Technologies

The world of gearboxes isn’t just about mechanical parts anymore. We’re seeing more electronics and advanced systems integrated into transmissions. Think about hybrid powertrains or even fully electric setups that are starting to appear. This means suppliers need to be ready to handle these new kinds of drivetrains. We’re talking about specialized electronic controls, more sensors, and parts designed for higher torque and better efficiency. It’s a pretty big jump from just dealing with old-school mechanical parts. Keeping up with these changes is how local businesses can stay relevant and offer modern solutions.

The automotive industry is always moving forward. Gearbox technology is no different. Suppliers and repairers in Australia need to be adaptable. They have to anticipate changes in vehicle design, global manufacturing, and new technologies. This preparedness is what allows them to meet the demands of modern transport and keep their businesses thriving.

Evaluating Potential Gearbox Part Manufacturers

When you’re looking for gearbox parts, especially for heavy-duty trucks or specialized vehicles, it’s not just about finding the cheapest option. You really need to dig into who is actually making these parts and if they know what they’re doing. Getting this right means your gearbox will last longer and perform better.

Key Manufacturing Hubs For Gearbox Components

Different places around the world have become known for making auto parts. When it comes to gearboxes, China is a big player. Regions like Guangdong are popular because they have lots of factories and good shipping connections, meaning parts can get to you faster. Jilin Province has a long history in the car industry and often works closely with big car makers, so they tend to focus on really strict quality. Then there are places like Zhejiang and Chongqing, which are getting known for newer technology and sometimes offer more budget-friendly choices.

Evaluating Supplier Technical Compliance And Certifications

This is where you need to be a bit of a detective. You can’t just take a supplier’s word for it. Look for certifications like IATF 16949. This is a big deal in the auto parts world and shows they follow strict quality rules. Also, ask for proof that the materials they use are good quality, like mill test reports for the steel. They should also be able to show you reports from machines that check if the parts are made exactly to the right size and shape, matching the original specs.

Here’s a quick checklist:

- Certifications: Do they have IATF 16949 or ISO 9001?

- Documentation: Can they provide material certificates and reports on part dimensions?

- Quality Control: Do they use tools like CMM (Coordinate Measuring Machines) to check parts?

You want to work with manufacturers who are open about their processes. If they’re willing to show you their factory, either in person or through a virtual tour, and can provide detailed reports on their quality checks, that’s a good sign. It means they’re confident in what they do and aren’t hiding anything.

Assessing Production Transparency And Audit Readiness

How open is the manufacturer about how they make their parts? Can you get reports on their production numbers or quality checks? Some suppliers are happy to let customers visit their factories or even conduct audits. This shows they have nothing to hide and are serious about quality. A manufacturer that is ready for audits and provides clear documentation about their production process is usually a safer bet. It means they’re likely to be consistent and reliable in the long run, which is exactly what you need when sourcing parts for something as important as a gearbox.

Specialized Gearbox Solutions For Diverse Australian Needs

Australia’s unique landscape and varied industries mean that a one-size-fits-all approach to gearboxes just doesn’t cut it. We’re talking about everything from tackling rough outback tracks to keeping massive industrial machines humming along. This means there’s a real need for gearboxes that are built for specific jobs, not just general use.

Gearboxes For Compact Off-Road Vehicles

Think about those smaller 4WDs and UTVs that people use for exploring, farming, or just getting around on properties. They need gearboxes that are tough enough to handle bumps and inclines but also compact enough to fit without taking up too much space. Suppliers are getting better at making these, balancing strength with a smaller footprint. It’s about getting that off-road capability without needing a massive vehicle.

High-Performance Motorsport Gearboxes

For the racing enthusiasts and performance car owners, standard gearboxes often aren’t up to the task. Motorsport demands gearboxes that can handle extreme forces, rapid gear changes, and the constant stress of competition. This often means looking at specialized units designed for durability and speed. Companies that focus on these high-performance applications understand the need for precision engineering and robust materials. They might offer options for specific racing classes or custom setups to match a vehicle’s unique power output. If you’re serious about performance, checking out places that specialize in TREMEC driveline parts can be a good start.

Custom Builds And Upgrades

Sometimes, off-the-shelf just won’t do. Whether you’ve got a classic car you’re restoring with a modern engine swap, or a piece of industrial equipment with very particular operational needs, custom gearbox solutions are key. This involves working closely with a supplier or manufacturer to design and build a gearbox that perfectly fits your requirements. It could be about achieving a specific gear ratio, handling a unique torque load, or fitting into a tight, unconventional space.

When you’re looking at specialized gearboxes, it’s not just about the unit itself. It’s also about the support and knowledge that comes with it. A good supplier will understand your application and help you choose or design the right solution, rather than just selling you a part.

Here’s a quick look at what goes into specialized solutions:

- Material Strength: Using high-grade alloys for gears and casings to withstand extreme stress.

- Cooling Systems: Integrating advanced cooling to prevent overheating during intense use.

- Ratio Customization: Tailoring gear ratios for optimal performance in specific applications (e.g., low-end torque for off-roading, high-speed gearing for racing).

- Durability Testing: Rigorous testing to ensure reliability under demanding conditions.

Wrapping It Up

So, finding the right gearbox supplier in Australia can seem like a big task, but hopefully, this guide has made it a bit simpler. Whether you need heavy-duty parts for a truck, something specific for a classic car, or just a reliable repair shop, there are good businesses out there ready to help. Keep in mind places like Wholesale Automatics for their huge part selection, Heavy Automatics if you’re dealing with Allison transmissions, and Mal Wood Automotive for TREMEC gear. A solid transmission is super important for your vehicle to run well and last a long time, so taking the time to pick the right supplier is definitely a smart move. Happy travels!

Frequently Asked Questions

What makes a gearbox built for really tough jobs?

Gearboxes made for tough jobs are built super strong to handle a lot of power and pressure, like those found in big trucks or heavy machines. They use tougher materials and smarter designs so they don’t break easily, even when working hard or carrying heavy loads.

Why are automatic transmissions becoming more popular in Australia?

More people in Australia are choosing automatic cars because they’re just easier to drive, especially in busy city traffic. Plus, they often use less fuel than older manual cars. Many new vehicles now come with automatic transmissions as the standard option.

How is a standard car gearbox different from one used in factories?

A regular gearbox is for everyday cars. But a special industrial gearbox is much stronger and made for specific, hard tasks in factories or on big machines. It needs to work all the time and be super reliable.

What should I check when buying parts for a gearbox?

When you’re buying gearbox parts, it’s smart to look at how strong the materials are and how well they were made. Also, find out if the company you’re buying from has a good reputation. Using good quality parts means your vehicle will run better for longer.

How do new car models from other countries affect gearbox suppliers here?

When car companies bring new models to Australia with advanced gearboxes, local suppliers need to be ready. They have to get the right parts and learn how to fix these new systems. This means they become more knowledgeable about gearboxes made all around the world.

Are there special gearboxes for smaller off-road vehicles?

Yes, there’s a growing need for gearboxes that are tough enough for off-roading but also small enough to fit into compact 4WD vehicles. Companies are working on making these strong, space-saving solutions for vehicles used in Australia’s diverse terrain.