Finding the right gearbox for your industrial setup can feel like a puzzle. You need something tough, reliable, and suited for the job, whether it’s for a mine, a farm, or a factory. That’s where a good supplier comes in. We’re talking about a Trusted Australian gearbox distributor who knows their stuff and can help you get exactly what you need without the fuss. Let’s look at what makes a good partner and what to expect.

Key Takeaways

- When picking a gearbox, think about what it’s for, the speed and power you need, and the conditions it’ll work in. Don’t forget about how easy it is to fix later.

- A good distributor in Australia means local help and support when you need it, which can save you time and headaches.

- Look for distributors who work with well-known brands and can show you different types of gearboxes, like planetary or geared motors.

- The best suppliers offer more than just sales; they can help with custom designs and ongoing service to keep your equipment running smoothly.

- Industries from mining and farming to construction and oil & gas all rely on dependable gearboxes to get their work done.

Understanding Your Industrial Gearbox Requirements

Before you even start looking at specific models or brands, it’s really important to get a handle on what your industrial gearbox actually needs to do. This isn’t just about picking something that looks good; it’s about making sure the equipment you rely on keeps running smoothly and efficiently. Think of it like buying a tool – you wouldn’t grab the first wrench you see if you needed to tighten a specific bolt, right? The same applies here, but with much bigger consequences if you get it wrong.

Defining Industrial Gearbox Applications

So, what exactly is this gearbox going to be doing? Is it part of a massive conveyor belt system moving materials in a factory, or is it powering a crucial piece of machinery in a mine? Maybe it’s for something in agriculture, like a harvester, or even part of a construction vehicle. Each of these jobs puts different demands on a gearbox. You need to know the basic function: is it primarily for reducing speed, increasing torque, or changing the direction of rotation? Understanding the core task helps narrow down the options considerably. For instance, a gearbox for a slow-moving, heavy-duty press will have very different needs than one for a high-speed packaging machine.

Key Considerations for Gearbox Selection

Once you know the application, you can start thinking about the nitty-gritty details. This is where you really dig into the specifics. The most critical factor is matching the gearbox’s specifications to your application’s demands.

Here are some things to really think about:

- Torque and Speed: How much twisting force (torque) does the gearbox need to handle, and at what speed? This is often the first thing engineers look at. You’ll need to know the input speed and the desired output speed to figure out the necessary gear ratio.

- Load Type: Will the load be constant, or will it vary? Is it a smooth, steady pull, or will there be sudden shocks and impacts? This affects the type of gearbox and the materials it needs to be made from.

- Duty Cycle: How long will the gearbox be running each day? Is it on 24/7, or only used intermittently? A gearbox running non-stop needs to be built much more robustly than one used for a few hours a week.

- Environmental Factors: Where will this gearbox be operating? Is it going to be exposed to extreme temperatures, dust, moisture, or corrosive chemicals? You’ll need a gearbox that can handle these conditions without failing prematurely.

- Space Constraints: How much room do you actually have to fit the gearbox? Some applications require very compact units, while others have plenty of space.

Choosing the right gearbox isn’t just about picking a product off a shelf. It involves a careful assessment of the operational demands, the environment it will work in, and the long-term maintenance considerations. Getting this initial assessment right saves a lot of headaches down the line.

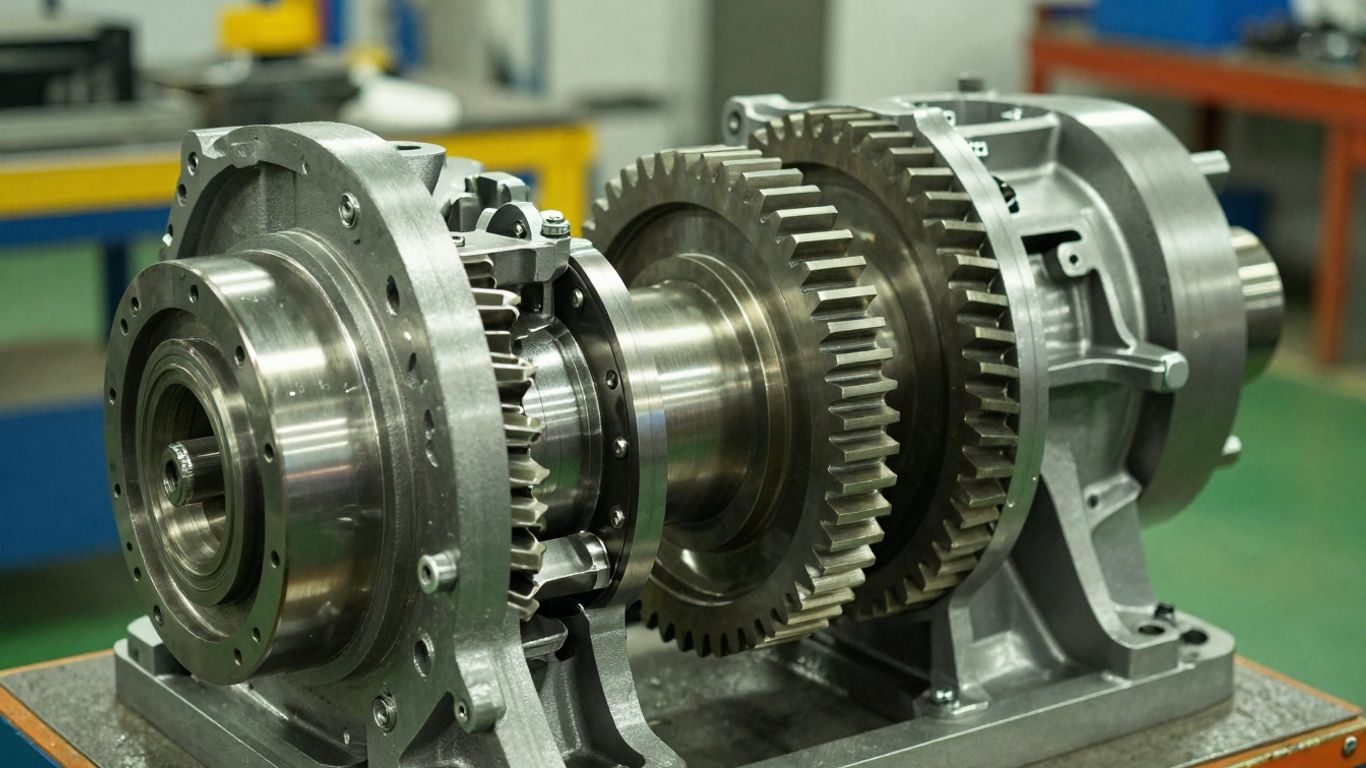

Types of Industrial Gearboxes Available

There are quite a few different kinds of gearboxes out there, and each has its own strengths. You’ll commonly see:

- Helical Gearboxes: These are known for being quiet and efficient, good for moderate to high speeds.

- Worm Gearboxes: Great for high reduction ratios and self-locking capabilities, often used when you need a lot of torque at a low speed.

- Planetary Gearboxes: These are compact and can handle high torque, making them popular for applications where space is limited but power is needed.

- Bevel Gearboxes: Used when you need to change the direction of rotation, often at a 90-degree angle.

- Geared Motors: These combine a motor and a gearbox into a single unit, simplifying installation and saving space.

Knowing the basic types and their typical uses is a good starting point. You can find more details on specific industrial gears and their applications to help you understand the options.

Partnering with a Trusted Australian Gearbox Distributor

Finding the right gearbox for your industrial setup can feel like a puzzle. You need something that’s tough, reliable, and fits your specific job. That’s where a good Australian distributor really shines. They’re not just selling parts; they’re offering solutions backed by local know-how.

Benefits of Local Expertise and Support

Working with a distributor based right here in Australia means you get support that understands our unique industrial landscape. Think about it: they know the local conditions, the common challenges businesses face, and can often get parts to you faster. Plus, dealing with someone in your own time zone makes communication a whole lot easier. It cuts down on delays and misunderstandings, which is a big win when your machinery is down.

- Faster response times: Local teams can often react quicker to your needs.

- Understanding of local regulations and standards: They know what’s required here.

- Easier logistics: Reduced shipping times and simpler import processes.

- Personalised service: Building a relationship with a local supplier can lead to better tailored advice.

What Makes a Gearbox Distributor Trusted

So, what separates a good distributor from just anyone? It’s a mix of things. First off, they’ll have a solid reputation built over time. Ask around, check reviews – see what other businesses say. A trusted distributor will also be upfront about their products, including where they come from and what they’re made of. They won’t shy away from questions about quality control or warranties. They stand behind the products they sell.

Here are a few signs of a trustworthy partner:

- Clear product information: They provide detailed specs and origin details.

- Strong supplier relationships: They work with reputable manufacturers.

- Good customer feedback: Positive reviews and testimonials.

- Transparent pricing and policies: No hidden fees or confusing terms.

- After-sales support: They’re there to help even after the sale.

A distributor’s real value isn’t just in the price tag; it’s in the confidence you gain knowing you’ve got a reliable partner who can help you keep your operations running smoothly. They act as a bridge between complex engineering and your practical needs.

Ensuring Quality and Reliability in Gearbox Supply

Quality isn’t just a buzzword; it’s what keeps your machines running and your projects on track. A top-tier Australian distributor will focus on supplying gearboxes built with robust materials and advanced manufacturing techniques. They’ll likely partner with well-known brands that have a proven track record for durability and performance. This means you’re getting gearboxes that can handle the tough demands of Australian industries, from the heat of the outback to the heavy loads in manufacturing plants. They should also be able to provide documentation or certifications that back up their quality claims, giving you peace of mind.

Exploring Leading Gearbox Brands and Technologies

When you’re looking for industrial gearboxes, you’ll find a lot of different brands and technologies out there. It can feel a bit overwhelming, but knowing what’s available helps you make a smarter choice. We’re talking about gearboxes from places known for making good mechanical stuff, like Italy, and also about the latest designs that pack a punch in a smaller size.

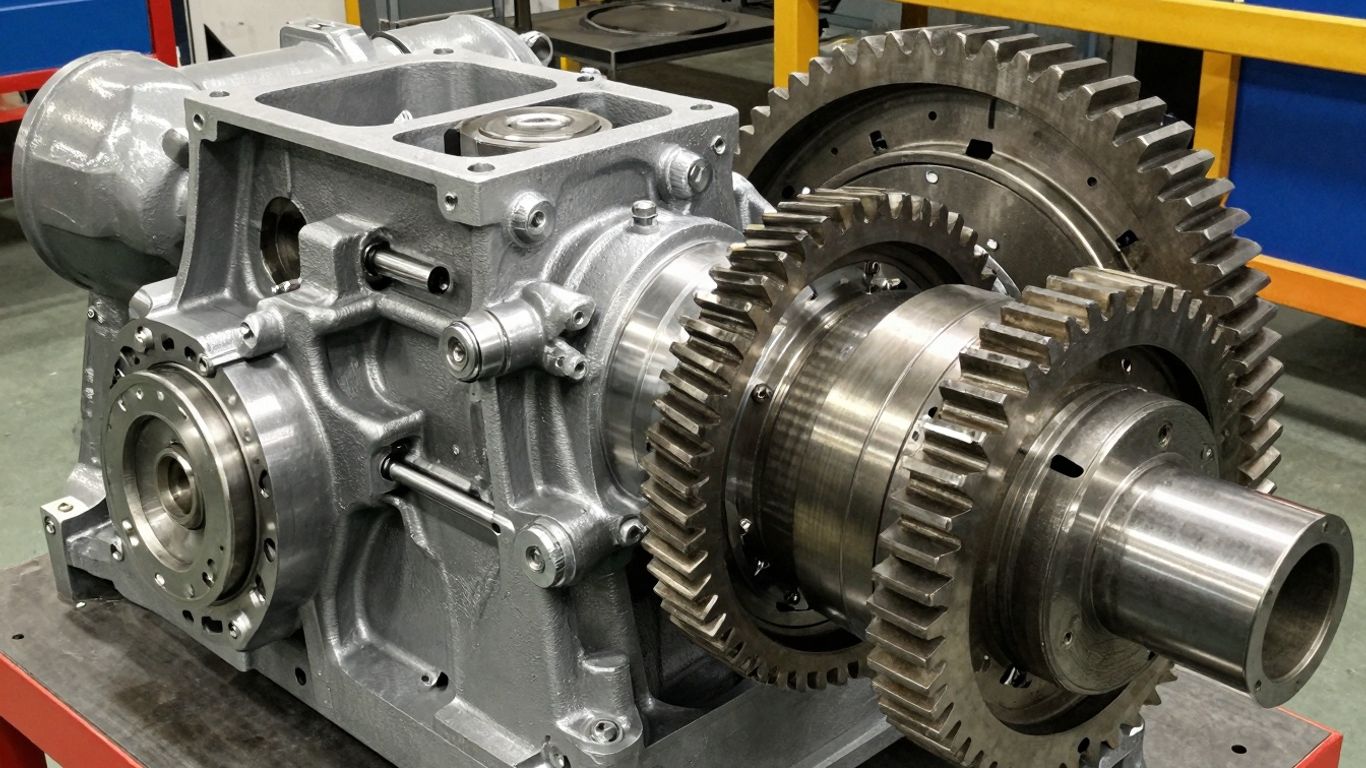

Renowned Italian Gearbox Manufacturers

Italy has a long history of making high-quality mechanical components, and gearboxes are no exception. Brands like Tramec, established back in 1986, are a good example. They focus on making gearboxes that are tough, can be mounted in different ways, and have a solid reputation in industries. They offer a variety of types, including bevel helical, parallel shaft, shaft-mounted, and right-angle gearboxes. This Italian craftsmanship means you’re often getting a product built with precision and a focus on durability. It’s good to know you can get these reliable Italian gearbox solutions right here in Australia.

Advanced Planetary and Geared Motor Solutions

Planetary gearboxes are a big deal in modern machinery. They’re known for being really efficient and can handle a lot of torque in a compact package. Manufacturers like Neugart have been specializing in these for decades, even developing things like hygienic designs for specific industries. Geared motors, which combine a motor and a gearbox into one unit, are also becoming more common. They simplify installation and save space, making them a popular choice for many applications where efficiency and a clean setup are important.

High-Torque and Compact Gearbox Designs

One of the trends in gearbox technology is making them smaller but more powerful. You’ll see terms like "high-torque" and "compact" used a lot. This means you can get the same power output as a larger, older gearbox but in a unit that takes up less space. This is a big win for machine design, allowing for more streamlined equipment. These advanced designs often use better materials and manufacturing techniques to achieve this performance. It’s all about getting more power and efficiency without the bulk.

Choosing the right gearbox technology often comes down to balancing performance needs with physical constraints and operational environment. The advancements in areas like planetary gearing and integrated geared motors are making it easier to find solutions that fit specific, demanding applications.

Here’s a quick look at some common types you might encounter:

- Helical Gearboxes: Good for general use, quiet operation.

- Worm Gearboxes: Offer high gear reduction ratios, often used for high torque applications.

- Planetary Gearboxes: Known for high efficiency, compact size, and high torque density.

- Geared Motors: Integrated units combining motor and gearbox for simplified design.

Comprehensive Services from Your Gearbox Partner

Customised Gearbox Design and Integration

Sometimes, off-the-shelf just doesn’t cut it. When your industrial setup has unique demands, a standard gearbox might not be the perfect fit. That’s where custom design and integration come in. A good distributor doesn’t just sell you a box; they help you get the right power transmission solution built for your specific machine or process. This could mean tweaking dimensions, altering shaft configurations, or even designing a completely new unit to match your exact needs. Getting this right means your equipment runs smoother and lasts longer. They’ll work with you to understand the torque, speed, and environmental factors, then engineer a solution that integrates perfectly.

Ongoing Maintenance and Servicing Options

Buying a gearbox is just the start. To keep your operations running without a hitch, regular maintenance is key. Think of it like servicing your car – it prevents bigger, more expensive problems down the road. A trusted partner will offer services like:

- Routine inspections: Checking for wear, leaks, and proper lubrication.

- Lubrication services: Using the correct oils and greases for your specific gearbox and operating conditions.

- Repair and rebuilding: If something does go wrong, they can often repair or completely rebuild your existing gearbox, saving you the cost of a new one.

- Performance monitoring: Using tools to check vibration and temperature, which can signal early issues.

Keeping your gearboxes in top shape isn’t just about avoiding breakdowns; it’s about maintaining efficiency and safety in your workplace. Regular check-ups can catch small issues before they become major headaches, saving you time and money.

Australia-Wide Distribution and Support Network

No matter where your business is located in Australia, you need a partner who can reach you. A distributor with a strong, Australia-wide network means you’re not left waiting for parts or technical advice. Whether you’re in a major city or a remote regional area, they should have the logistics in place to get you what you need, when you need it. This includes:

- Stock availability: Keeping a good range of common gearboxes and parts on hand.

- Efficient shipping: Reliable delivery across the country.

- Local technical support: Having people you can talk to who understand your local conditions and challenges.

- Branch network: Physical locations for easier access and consultation.

Industries Benefiting from Reliable Gearboxes

It’s pretty wild how many different places you find industrial gearboxes working hard. Honestly, they’re the unsung heroes in so many operations, making sure everything runs smoothly. Without them, a lot of the stuff we rely on daily just wouldn’t get done.

Gearbox Solutions for Mining and Manufacturing

In the mining sector, gearboxes are put through the wringer. Think about crushing rocks or moving massive amounts of ore – that takes some serious power and torque. Gearboxes here need to be tough, really tough, to handle the dust, heavy loads, and constant operation. They’re essential for conveyor systems, crushers, and haul trucks. Similarly, manufacturing plants depend on precise speed and torque control. Whether it’s an assembly line moving at a steady pace or a machine performing a delicate task, the right gearbox makes all the difference. A reliable gearbox means less downtime and more consistent product quality. For these demanding environments, you’ll often see heavy-duty reduction gearboxes and robust planetary units being used.

Applications in Agriculture and Construction

Farming and building sites are another big area. On farms, gearboxes are found in everything from tractors powering ploughs and harvesters to automated feeding systems. They help adjust the speed of machinery to suit different tasks, like tilling soil versus harvesting crops. In construction, think about cranes lifting heavy materials, concrete mixers, or even drilling equipment. These applications require gearboxes that can handle sudden load changes and operate reliably in dusty, outdoor conditions. You might find specialized gearboxes like post hole digger units or slasher gearboxes being used here.

Serving the Oil & Gas and Marine Sectors

These industries often deal with harsh environments and require equipment that can withstand corrosion and extreme conditions. In the oil and gas sector, gearboxes are used in drilling rigs, pumps, and processing equipment. They need to be dependable, as failures can be incredibly costly and dangerous. The marine industry also relies heavily on gearboxes for propulsion systems on ships and boats, as well as for operating winches and cranes on offshore platforms. These units must be built to resist saltwater and operate efficiently for long periods. Finding a distributor with a good range of inline helical gearboxes is key for many of these applications.

Choosing the right gearbox isn’t just about picking a part number. It’s about understanding the specific demands of your operation, the environment it will work in, and the long-term reliability you need. A good distributor can help you sort through the options and find a solution that fits perfectly.

Here are some common gearbox types you’ll encounter:

- Heavy-duty reduction gearboxes

- Planetary gearboxes

- Worm gearboxes

- Geared motors

- Helical bevel gearboxes

Wrapping Up Your Gearbox Search

So, finding the right gearbox distributor in Australia might seem like a big task, but it doesn’t have to be. Think about what your machinery really needs – the tough jobs, the specific tasks, and even the environment it’ll be working in. When you connect with a distributor, ask questions. They’re there to help you figure out the best fit, whether it’s a heavy-duty worm gearbox for a tough industrial setting or a precise planetary unit for something more delicate. Getting this right means your equipment runs smoothly, saving you headaches and downtime down the road. Don’t hesitate to reach out to the experts; they’ve got the knowledge to point you in the right direction.

Frequently Asked Questions

What exactly do industrial gearboxes do?

Industrial gearboxes are like the ‘muscle’ for machines. They help transfer power from one part of a machine to another. Think of them as helpers that can change how fast something spins, how much force it has, or even the direction it’s turning. This is super important for making things in factories, moving stuff around, and lots of other jobs.

How do I pick the best gearbox for my needs?

Choosing the right gearbox is like picking the right tool for a job. First, think about what the machine needs to do – how fast, how strong, and what it’s lifting. Then, consider the ‘gear ratio,’ which is how much it changes the speed and power. Also, think about where the machine will work (hot, cold, dusty?) and if it’s easy to fix later. Asking for advice from experts is always a good idea!

What happens if my gearbox breaks down?

If a gearbox has a problem, it’s important to get it checked out quickly. Sometimes, it just needs a little fix, like new oil or a small part. Other times, it might need a bigger repair, where someone takes it apart, cleans it, and puts it back together. Having a good plan for checking and fixing your gearboxes can save you a lot of trouble later.

What are the main types of gearboxes I might see?

There are many kinds! You’ll find ones called ‘planetary’ gearboxes, which are strong and compact. ‘Worm’ gearboxes are good for big speed changes. ‘Helical’ gearboxes are quiet and efficient. There are also ‘geared motors,’ which combine a motor and a gearbox into one unit. The best type depends on what you need it to do.

Why should I buy a gearbox from an Australian company?

Buying from an Australian distributor means you get local help and support. They understand the Australian environment and industries. Plus, if you need a part quickly or have a question, they’re right here, making things easier and faster for your business.

What makes a gearbox distributor ‘trusted’?

A trusted distributor offers good quality gearboxes that last a long time. They also have knowledgeable staff who can help you choose the right one and offer support if you have problems. They are honest about their products and have a good reputation for reliability and customer service.